Understanding 400 Meter Running Track Dimensions

Grasping the specifics of 400 meter running track dimensions is essential for athletes, coaches, and sports enthusiasts alike. The typical 400 meter track is designed with precision, adhering to regulations set by the International Association of Athletics Federations (IAAF). This standardization ensures fairness and consistency in athletic competitions around the globe.

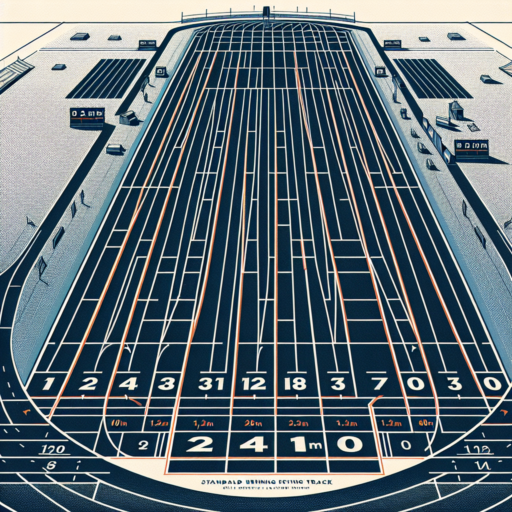

The anatomy of a 400 meter track encompasses various elements that contribute to its functionality and compliance with global standards. At its core, the track consists of two parallel straightaways and two semicircular bends. The inside length of the track, measured 30 centimeters from the innermost lane, marks the 400 meter distance accurately. Understanding the layout and dimensions of the track is crucial for strategic race planning and training.

Moreover, the lane width on a standard 400 meter track is another vital component, usually measuring 1.22 meters wide. This specification is critical for maintaining the integrity of the race distances across all lanes. Lane assignments in competition can significantly impact an athlete’s performance, making the knowledge of track dimensions and their implications a key aspect of competitive running.

The Regulation Size of a 400 Meter Running Track

The regulation size for a 400 meter running track plays a pivotal role in ensuring uniformity in athletic competitions globally. Governed by the International Association of Athletics Federations (IAAF), the standard dimensions set the stage for records and achievements in the world of track and field. Understanding these dimensions not only benefits athletes and coaches but also aids in the design and construction of athletic facilities.

Key Features of a Standard 400 Meter Track

The hallmark of a regulation 400 meter track lies in its precise length, which is meticulously measured along the innermost lane, known officially as Lane 1. The track comprises two parallel straight paths connected by two curved sections, with the radius of each curve precisely defined to maintain the official distance. Additionally, the track includes eight lanes, each with a standard width of 1.22 meters (4 feet), allowing for fair and competitive racing conditions.

The significance of adhering to the regulation size extends beyond ensuring equal competition; it also influences the training and performance of athletes. By practicing on a standard-sized track, runners can accurately gauge their speed, pacing, and endurance—critical elements for excelling in races. Moreover, the consistency in track dimensions allows for the accurate comparison of records and performances across different venues worldwide.

Key Features of a Standard 400 Meter Running Track

The physical layout and dimension of a standard 400-meter running track are subjects of specific regulations, designed to ensure uniformity and fairness in competitive athletics. A few key features define the archetype of these tracks, which are embraced globally.

Material and Surface

The surface of a standard 400-meter track is typically made from synthetic materials, such as polyurethane or latex, to provide athletes with a blend of grip and bounce. This not only enhances performance but also plays a critical role in minimizing the risk of injury. Safety and consistency are paramount, with the material also being weather-resistant to maintain its condition year-round.

Lane Design

Every standard track comprises eight lanes, each 1.22 meters wide, with the innermost lane being the shortest distance. The lanes are clearly demarcated and numbered, ensuring fairness and clarity during races. An important aspect is the inclusion of lane stagger in track design, compensating for the curve, so that all athletes run the same distance regardless of their starting position.

Oval Shape and Inner Field

The iconic oval shape of the 400-meter track encompasses two parallel straights and two semicircular bends. This standard layout is designed to contain a field within its bounds, which is typically used for field events such as javelin, discus, and long jump. The strategic design ensures efficient use of space, allowing a track and field meet to proceed smoothly and without interference between events.

How to Measure the Dimensions of a 400 Meter Running Track

Measuring the dimensions of a 400 meter running track involves understanding its layout and the precise methods used to ensure accuracy. A standard 400 meter track is designed to facilitate various track and field events, encompassing lanes that need to be accurately measured to maintain fairness in competitions. This task requires attention to detail and a grasp of specific measurement techniques.

Understanding the Structure of the Track is the first step in accurate measurement. Traditional 400 meter running tracks are oval-shaped, consisting of two parallel straightaways and two curved sections. The innermost lane, ideally, measures 400 meters in length, with each subsequent lane being slightly longer. It’s crucial to comprehend that the measurement is taken from the inner edge of the track (the line closest to the field) to ensure uniformity across various facilities.

To accurately measure a 400 meter running track, specialized equipment and methodologies are essential. A calibrated measuring wheel or a surveyor’s tape measure is typically used, starting at the «finish line» and following the path of the innermost lane. Keeping the measuring device on the ground and as close to the inner lane line as possible will yield the most accurate results. Additionally, taking several measurements and averaging them can help eliminate errors and improve precision.

Variations in 400 Meter Running Track Dimensions

When examining variations in 400 meter running track dimensions, it’s important to understand that while the length remains consistent, several other factors contribute to the differences in design and construction. These variations can influence the training and competition environments for athletes across various levels of competition.

One significant variable is the width of the lanes. Regulation tracks often feature lanes that are 1.22 meters wide, but this dimension can vary slightly depending on the facility’s specifications and the governing body’s regulations. Such variations can affect the total number of lanes a track can accommodate, impacting not only individual races but the logistics of hosting larger track and field events.

Another aspect to consider is the radius of the curves on the track. Tracks are designed with two semicircular curves that connect the straight sections. The standard radius is set to optimize the balance between the length of the straights and the tightness of the curves, aiming to provide a fair and competitive racing environment. However, due to spatial constraints or architectural decisions, some tracks may feature tighter or broader curves, which can subtly influence runners’ strategies and performance, especially in lane assignments for races that include the curves.

In addition to the lane width and curve radius, the surface material and the incline of the track can also vary. These differences can affect runners’ speed and fatigue levels, potentially contributing to the overall performance variability among athletes. Tracks are typically composed of synthetic materials that offer a balance of grip and bounce, promoting higher speeds and safer conditions. Nonetheless, the specific choice of material and any presence of incline can slightly alter the dynamics of a race.

Understanding these variations is crucial for athletes, coaches, and sports scientists alike, as it allows for better preparation and strategy development tailored to specific track designs. Each element, from lane width to curve radius and surface characteristics, plays a subtle yet influential role in the sport of track and field, underscoring the importance of familiarity with different track dimensions.

Design Considerations for Building a 400 Meter Running Track

When embarking on the construction of a 400 meter running track, several pivotal design considerations must be taken into account to ensure the track meets both athlete requirements and regulatory standards. Primarily, the surface material is a key factor that can greatly influence the performance levels and safety of users. High-quality synthetic materials, such as polyurethane, offer superior durability and shock absorption, enhancing the overall running experience.

Moreover, the geometric layout of the track is another crucial aspect that demands careful planning. The standard oval shape must have precise curvature and lane width to facilitate fair competition and accommodate the maximum number of athletes comfortably. This necessitates the use of sophisticated design software and adherence to international guidelines set forth by bodies such as the International Association of Athletics Federations (IAAF).

Drainage and Water Management also play a significant role in the longevity and maintenance of a 400 meter running track. Effective systems must be in place to prevent water accumulation, which can lead to surface degradation and pose safety risks to athletes. Incorporating adequate slopes and installing high-quality drainage solutions are paramount to avoid disruptions and ensure the track remains in optimal condition for competition and training sessions.

Recommended Surface Types for 400 Meter Running Tracks

Choosing the right surface for a 400-meter running track is crucial for enhancing performance and reducing the risk of injuries. With several options available, it’s important to consider the specific needs of athletes and the local climate when selecting a track surface. Below are some of the most recommended types of surfaces for 400-meter tracks that cater to a wide range of requirements.

Synthetic Surfaces

Synthetic tracks have become the standard for competitive athletics due to their durability and all-weather capabilities. Made primarily from polyurethane, these surfaces provide a consistent performance level, excellent traction, and shock absorption. Athletes find synthetic tracks beneficial for reducing the impact on their joints, making it an ideal choice for training and competitions alike. Its water-resistant properties ensure that the track remains usable even after rain, making it a versatile option for various climates.

Latex or Recycled Rubber Surfaces

For eco-conscious organizations, latex or recycled rubber tracks offer a sustainable alternative without compromising on performance. These surfaces are known for their excellent resilience and ability to withstand heavy use. While they may not match the elite performance characteristics of polyurethane surfaces, they still provide ample shock absorption and a fair degree of spring, aiding in athlete protection. Additionally, their lower cost makes them a practical choice for community tracks or training facilities with budget constraints.

Water-Based Surfaces

Though less common, water-based track surfaces are noteworthy for their ultra-smooth texture and enhanced performance features. These tracks tend to offer superior speed capabilities, making them a favorite among sprinters. However, their maintenance requirements and sensitivity to weather conditions limit their applicability to certain regions. Despite these challenges, for facilities that can accommodate their needs, water-based tracks provide an exceptional running experience.

Maintaining Your 400 Meter Running Track for Optimal Performance

Maintaining a 400 meter running track is essential for optimal performance and safety. Regular maintenance ensures that the track surface remains in top condition, providing athletes with the consistency they need for training and competition. Understanding the key aspects of track maintenance can significantly extend its lifespan and improve overall user experience.

Regular Cleaning and Debris Removal

Regular cleaning is the first step in maintaining your 400 meter running track. It’s crucial to remove dirt, leaves, and other debris that can accumulate on the surface. These materials not only make the track less appealing but can also degrade the track material over time and create unsafe conditions for runners. Implementing a routine cleaning schedule ensures the track stays in prime condition and safe for every runner.

Surface Inspection and Repair

Periodic surface inspections are vital for identifying any issues such as cracks, bubbles, or areas of wear and tear that may affect the track’s performance or athlete safety. Early detection of these problems allows for timely repairs, preventing further damage and potentially costly overhauls down the line. Specialized repair materials should be used to fix any identified issues, ensuring the repairs are durable and blend seamlessly with the existing track surface.

No se han encontrado productos.

How 400 Meter Track Dimensions Influence Athlete Performance

Understanding the impact of 400 meter track dimensions on athlete performance is crucial for both coaches and competitors. The standardized size and shape of these tracks play a significant role in how athletes train, compete, and succeed in track and field events. The precise 400m distance, along with the track’s layout, dictates the strategy and physical demands placed on runners.

The curvature of the track is a critical aspect that can affect an athlete’s speed and stamina. A standard 400m track consists of two straight sections and two curved sections. Athletes must navigate these curves strategically to maintain speed without expending unnecessary energy. The tighter the curve, the more challenging it is for runners to maintain their pace, which is why proper lane allocation based on qualifying times is essential for fair competition.

Another factor to consider is the influence of track surface material on performance. Modern tracks are designed with synthetic materials that provide optimal traction and shock absorption. These advancements in track technology help reduce the risk of injuries and allow athletes to push their limits with confidence. The interaction between the athlete’s shoes and the track surface can significantly impact speed and efficiency, highlighting the importance of equipment choice in competitive track and field.

Running on different lanes also plays a pivotal role in performance due to the varying distances each lane represents on a curve. Athletes in the inner lanes have a shorter distance to cover, but they also face tighter curves, requiring more precision in their stride and turn technique. Conversely, those in outer lanes can maintain a steadier pace with less drastic turns but need to run slightly longer distances. Balancing these factors is crucial for maximizing performance on a 400m track.

World-Class Facilities: A Look at Olympic 400 Meter Running Tracks

The allure of the Olympic 400 meter running tracks is not merely in the events they host but in their state-of-the-art design and engineering. These world-class facilities are a pinnacle of sports architecture, designed to meet the exacting demands of elite competition, while also enhancing athlete performance. The standard for these tracks is set by the International Association of Athletics Federations (IAAF), ensuring every track meets specific criteria for surface, incline, and length.

Olympic 400 meter running tracks are marvels of modern engineering. Constructed with specialized synthetic surfaces, they are designed to provide optimal traction and minimize injuries. The typical layout includes eight lanes, each 1.22 meters wide, with a total length of 400 meters in the innermost lane. This precision ensures fairness and consistency across competitions. Furthermore, the attention to detail extends to the incline of the track, which is carefully calculated to compensate for the centrifugal force athletes experience on the curves.

The evolution of these tracks reflects advancements in materials science and engineering insights. Initially made from cinder or other natural materials, today’s surfaces are synthetic, offering athletes improved shock absorption and superior speed capabilities. This shift has been instrumental in breaking records and pushing the boundaries of human performance.