No se han encontrado productos.

What is the resistance range of a 10K thermistor?

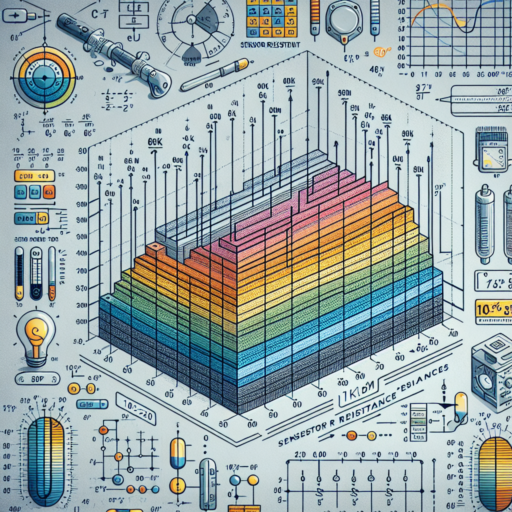

The resistance range of a 10K thermistor is a critical parameter for engineers and hobbyists who use these components in temperature sensing applications. Typically, a «10K» designation means that the thermistor has a nominal resistance of 10,000 Ohms at 25 degrees Celsius (77 degrees Fahrenheit). However, it’s essential to understand that the resistance range of a 10K thermistor can vary significantly depending on changes in temperature, given that thermistors are temperature-dependent resistors.

The actual resistance range of a 10K thermistor can span much lower or higher than 10,000 Ohms because its resistance decreases with an increase in temperature for Negative Temperature Coefficient (NTC) thermistors, or increases for Positive Temperature Coefficient (PTC) thermistors. For NTC thermistors, which are more commonly used for temperature sensing, the resistance can drop to a few hundred Ohms at high temperatures, or it can increase to several tens of thousands of Ohms at low temperatures.

It’s also important to highlight the importance of consulting the specific thermistor’s datasheet for its resistance-temperature curve. This curve will provide detailed information on the resistance values over the expected temperature range it might encounter in its application environment. Applications utilizing a 10K thermistor span from simple temperature sensors in home thermostats to critical monitoring devices in medical and industrial equipment, making understanding the resistance range crucial for their correct function and reliability.

Are all 10K thermistors the same?

When exploring the realm of 10K thermistors, a common misconception is that all these components are virtually identical. However, this is far from the truth. Despite sharing a foundational characteristic—having a resistance of 10,000 Ohms at 25°C (77°F)—the similarities often end there. 10K thermistors can drastically vary in terms of their temperature coefficient, tolerance, and operational range, among other specifications.

Different Temperature Coefficients

One notable aspect where 10K thermistors differ is their temperature coefficient. This property determines how the resistance of the thermistor changes as temperature changes. There are primarily two types: NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient). NTC thermistors decrease in resistance as temperature increases, while PTC thermistors do the opposite. Depending on the application, choosing the correct type is crucial for accurate temperature sensing and control.

Tolerance Variations

Another key point of variability among 10K thermistors is their tolerance, which refers to how much the actual resistance can deviate from the stated 10,000 Ohms at 25°C. Tolerances can range significantly, from as tight as ±0.1% to as broad as ±5% or even more in some cases. Tighter tolerances are typically sought after in applications that demand higher precision in temperature measurement and control.

In summary, while 10K thermistors may appear to be a standardized component at first glance, a closer examination reveals a complex landscape of variations. These differences are not trivial but are critical for engineers and designers to consider when selecting a thermistor for their specific application needs. Whether it’s the temperature coefficient, tolerance, or another specification, understanding these nuances is key to optimal performance and reliability..

What is the value of a 10K NTC thermistor?

Understanding the value of a 10K NTC thermistor is essential for those involved in electronics and thermal management fields. Essentially, a 10K NTC (Negative Temperature Coefficient) thermistor is a type of resistor whose resistance decreases as the temperature increases. This characteristic makes it invaluable for measuring temperatures and creating more efficient circuit designs. Typically, the «10K» denotes that the thermistor has a resistance of 10,000 Ohms at 25°C (77°F). This standardized benchmark allows for easier integration and comparison across various applications and devices.

The functionality of a 10K NTC thermistor is deeply impacted by its coefficient value. The coefficient value indicates how drastically the resistance changes with a change in temperature. For a 10K NTC thermistor, this information is critical in designing temperature-sensitive circuits. Whether being used in simple temperature sensing circuits or sophisticated climate control systems, understanding this value allows engineers to accurately gauge and predict the performance of their systems under varying thermal conditions.

Moreover, the value of a 10K NTC thermistor goes beyond its resistance and coefficient; it’s also about versatility and reliability. These thermistors are widely used due to their sensitivity, small size, and ease of integration into a variety of devices, from household electronics to industrial machinery. They are favored for not just their technical specifications but for their durability and response time as well, providing a quick and accurate means of temperature monitoring and control.

What is the range of a 10K Type 3 sensor?

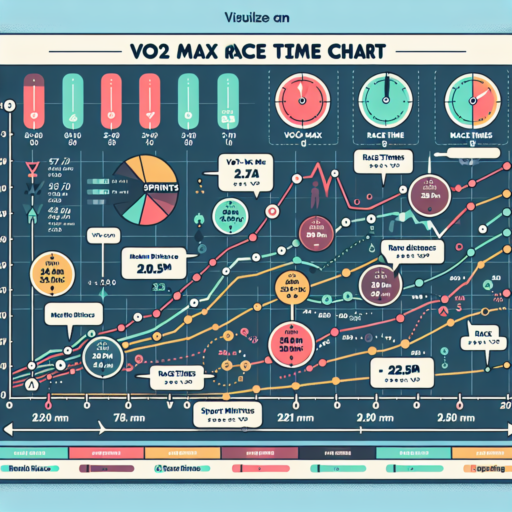

Understanding the range of a 10K Type 3 sensor is critical for ensuring its effective use across various applications. These sensors, renowned for their precision and reliability, operate within a specific temperature boundary that defines their optimum functionality. The term «10K» refers to the sensor’s resistance value at 25°C (77°F), which is 10 kilohms, and «Type 3» designates the particular thermistor curve or response characteristic established by standards.

The temperature range of a 10K Type 3 sensor is typically from -40°C to +105°C (-40°F to +221°F). Within this spectrum, the sensor exhibits a predictable resistance change in response to temperature variations, making it a versatile choice for a wide array of applications. From HVAC systems to automotive temperature monitoring, the precision of the 10K Type 3 sensor ensures it provides reliable readings, contributing to the overall efficiency and safety of these systems.

Moreover, it’s imperative to consider that these sensors must be matched with compatible circuitry designed to accurately interpret the resistance changes across the specified temperature range. Utilizing high-quality sensors and components can significantly enhance the performance and reliability of the monitoring or control system they are integrated into. Whether in industrial controls, consumer electronics, or environmental monitoring, the 0K Type 3 sensor stands out for its responsiveness and durability within its operational temperature limits.